Polyurethane Structural Foam

We specialize in providing comprehensive information about this versatile material and its myriad applications across various industries. Polyurethane structural foam is a game-changer, offering a lightweight, durable, and cost-effective alternative to traditional materials. Whether you’re in automotive, construction, furniture, or any other industry, this page will equip you with the knowledge to harness the power of polyurethane structural foam for your projects. Explore its benefits, applications, and the endless possibilities it offers.

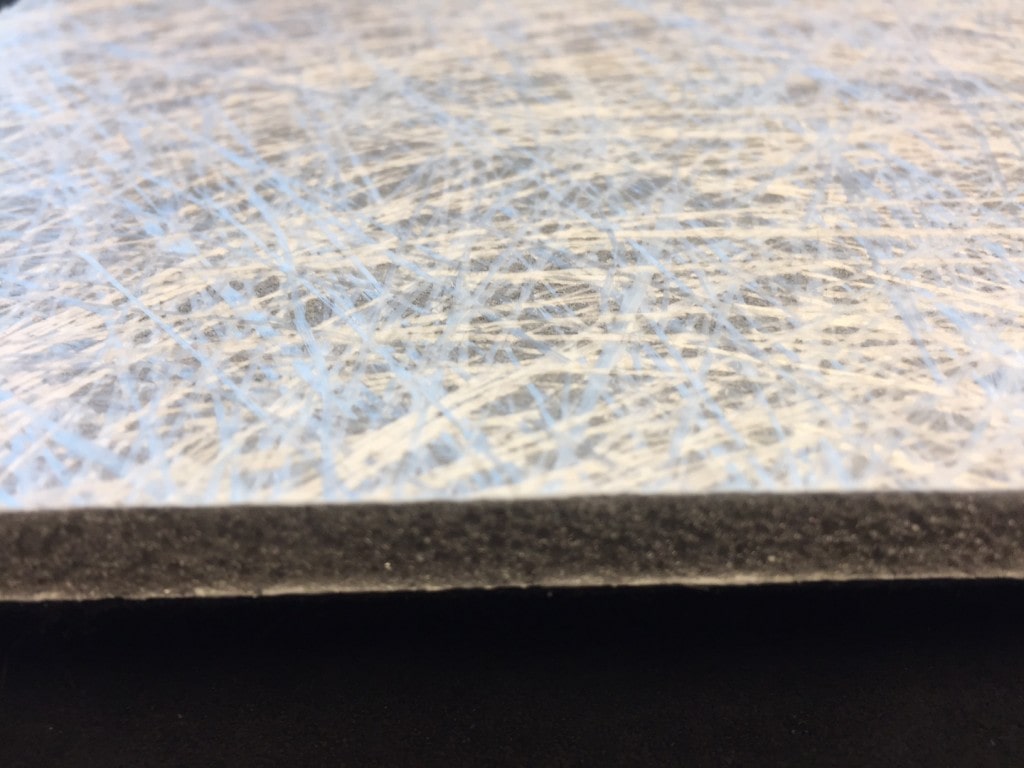

When combined with fiberglass chopped strand mats and adhesives our foams help create the strength necessary to support today’s modern day overhead systems. Our foam chemistry has a proven track record in automotive and commercial vehicle interiors. Lower density foams are available for under hood sound absorption applications. When combined with adhesives and scrims, our hoodliner composites can be thermoformed into aesthetically pleasing and excellent sound absorption engine compartments components. These components meet the toughest OEM flammability requirements.

Polyurethane structural foam is a unique material renowned for its exceptional properties, making it ideal for a wide range of applications. This advanced foam combines the advantages of lightweight construction, excellent strength-to-weight ratio, and impressive durability, revolutionizing industries that demand high-performance and cost-effective solutions. On this page, we delve into the many facets of polyurethane structural foam, highlighting its benefits and providing insights into its diverse applications.

Benefits of Polyurethane Structural Foam:

Lightweight Construction:

Polyurethane structural foam offers significant weight savings compared to traditional materials like metals and solid plastics. This lightweight nature translates into improved fuel efficiency, increased payload capacity, and easier handling during installation or assembly.

Exceptional Strength-to-Weight Ratio:

Despite its lightweight composition, polyurethane structural foam exhibits remarkable strength and rigidity. It provides excellent structural support and can withstand high loads and impacts, ensuring long-lasting and reliable performance.

Enhanced Durability:

Polyurethane structural foam is highly resistant to wear, tear, and degradation caused by exposure to harsh environments, chemicals, and UV radiation. It maintains its integrity over time, reducing maintenance and replacement costs.

Cost-Effectiveness:

The manufacturing process for polyurethane structural foam offers cost advantages compared to other materials. Its efficient production, low tooling costs, and reduced energy consumption contribute to overall cost savings without compromising on quality or performance.

Applications of Polyurethane Structural Foam:

Automotive Industry:

Polyurethane structural foam finds extensive use in automotive applications, including bumpers, body panels, interior components, and seating systems. Its lightweight nature enhances fuel efficiency, while its exceptional strength and impact resistance ensure passenger safety.

Construction and Building:

In the construction industry, polyurethane structural foam is employed for insulation panels, wall systems, roofing materials, and composite structures. Its insulation properties contribute to energy efficiency, while its lightweight construction facilitates faster and easier installation.

Furniture and Bedding:

Polyurethane structural foam provides the foundation for comfortable and supportive furniture and bedding products. It offers optimal cushioning, longevity, and dimensional stability, ensuring enhanced user comfort and durability.

Marine and Recreational Vehicles:

The marine industry benefits from polyurethane structural foam in boat hulls, decks, and flotation devices. Its buoyancy, resistance to water absorption, and corrosion resistance make it an excellent choice for marine applications. It is also used in recreational vehicles for lightweight construction and insulation purposes.

Industrial Equipment:

Polyurethane structural foam is utilized in the manufacturing of industrial equipment, such as machinery components, enclosures, and supports. Its ability to dampen vibrations and its resistance to chemicals and environmental factors make it an ideal material for industrial settings.

Polyurethane structural foam offers a wide array of benefits and applications across diverse industries. Its lightweight construction, exceptional strength-to-weight ratio, durability, and cost-effectiveness make it an attractive choice for manufacturers seeking innovative and efficient solutions. By exploring the possibilities of polyurethane structural foam, you can unlock new opportunities, enhance product performance, and gain a competitive edge in your industry.

Available Products:

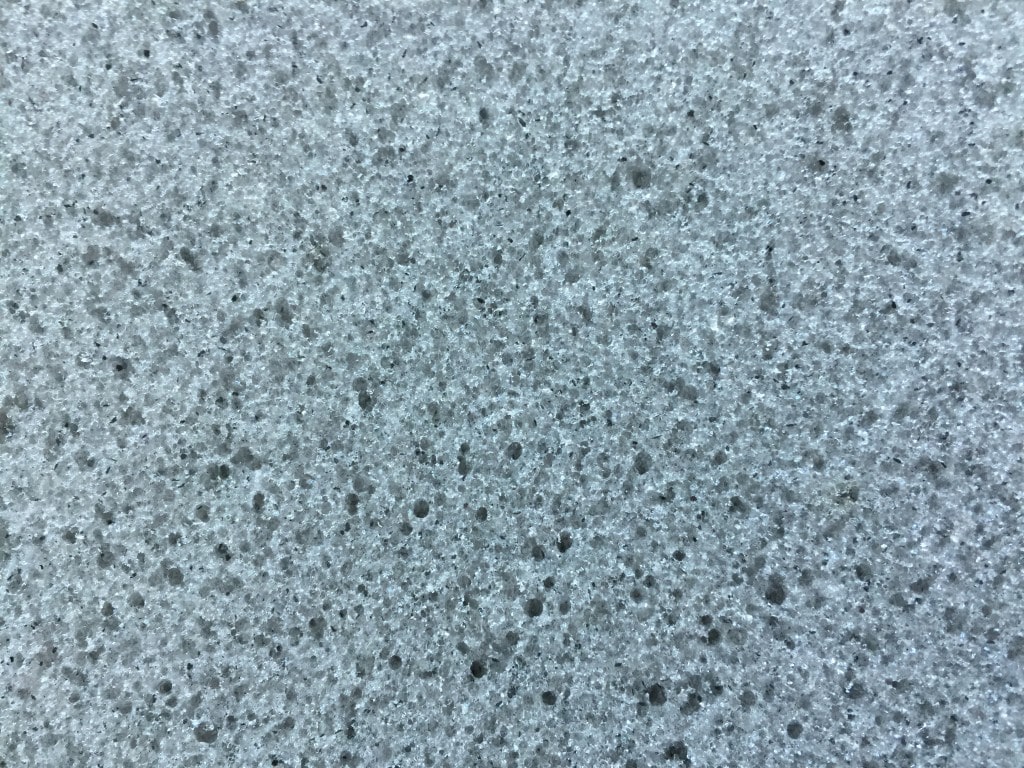

PU Semi Rigid Foam Blocks or Sheets

- 1.0pcf to 2.75pcf densities

- Structural PU layer for headliners, sunshades, and hoodliners

- Can be used in both cold and hot mold forming processes

- Available in blocks and/or sheets 5mm to 25mm thick

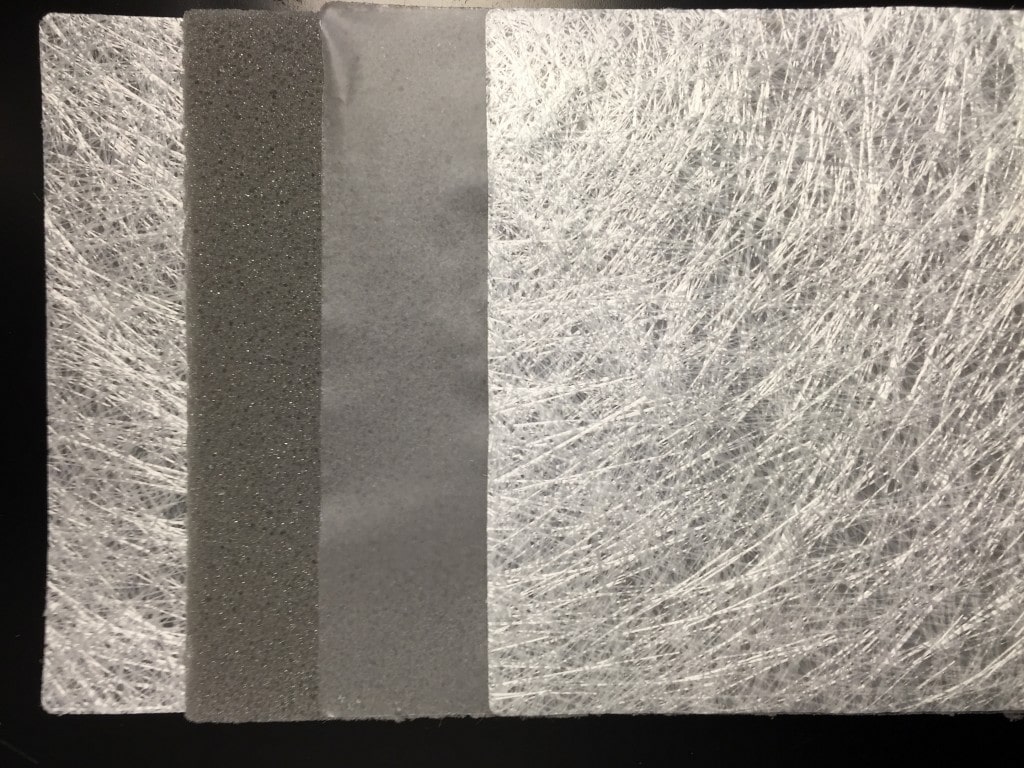

PU Semi Rigid Foam Composites for Hoodliners

- 1.0pcf to 1.5pcf densities

- Available in sheets 10-25 mm thick

- Can meet rigorous flammability requirements

- Can be thermally formed in both hot and cold molding processes

PU Semi Rigid TRU Boards

- 100% vertically integrated composite board manufacturer. Our Thermo-formable (TRU) sandwich boards incorporate our in-house chopped fiberglass tech mat technology. We can laminate chopped glass, adhesive films, PU foam, and scrims together in a single pass lamination process!

- 1.9pcf to 2.75pcf density foam is combined with chopped strand E-glass, adhesives films, powder binders, and scrims to meet your strength requirements.

- Our TRU boards are designed for use in cold mold forming processes

- Typical thickness of 7-10mm

- Typical composite weights of 800-1600gsm

Typical Products:

• Headliners

• Sunshades / Moon Roofs

• Hoodliners

• Under hood absorbers