Multilayer Composite Lamination

At HR Technologies, decades of experience and homegrown lamination capabilities allow us to efficiently bond all types of materials.

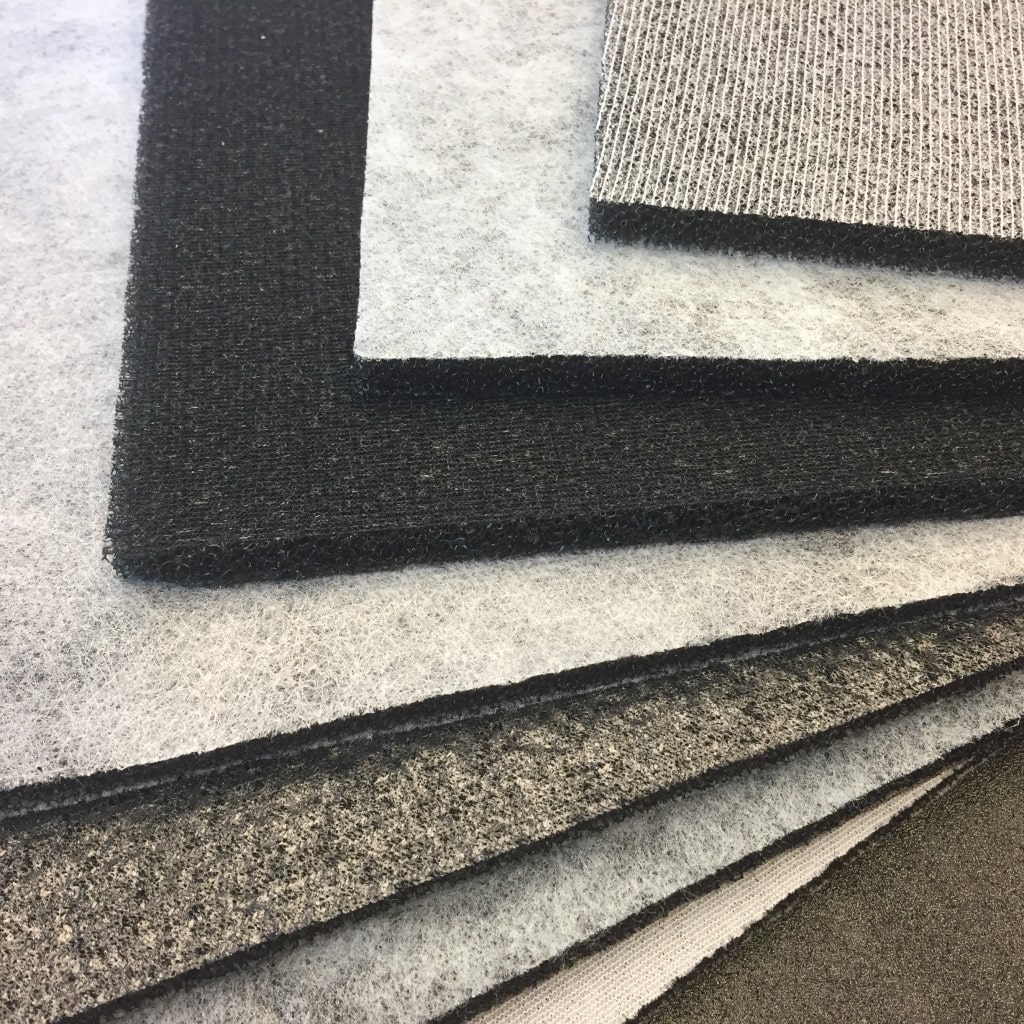

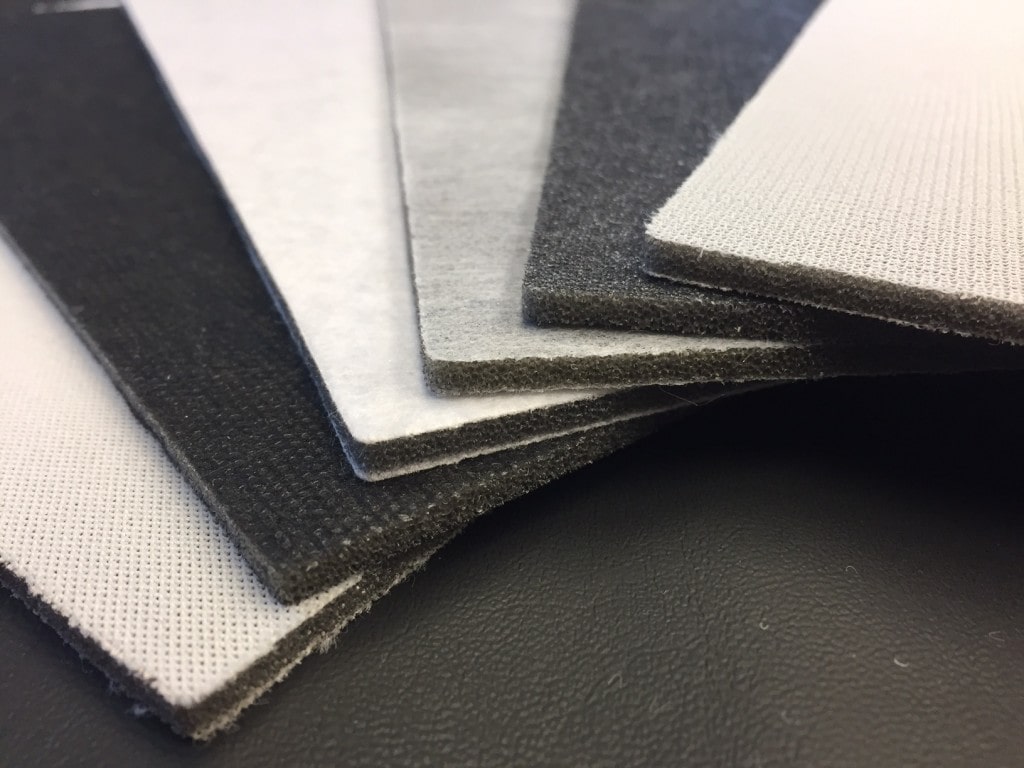

Multilayer composite lamination has emerged as a game-changing technique in the automotive and industrial sectors, offering efficient and reliable bonding for a wide range of materials. With applications spanning climate control seats, door bolsters trim, instrument panel trim, center console trim, headliners, and rigid urethane load floors, this advanced lamination process delivers superior performance and durability.

In most cases, we can bond multiple layers into a single composite in one operation. This efficient process allows us to be competitive in any market without jeopardizing quality. Call us today to discuss your next project.

-

Understanding Multilayer Composite Lamination:

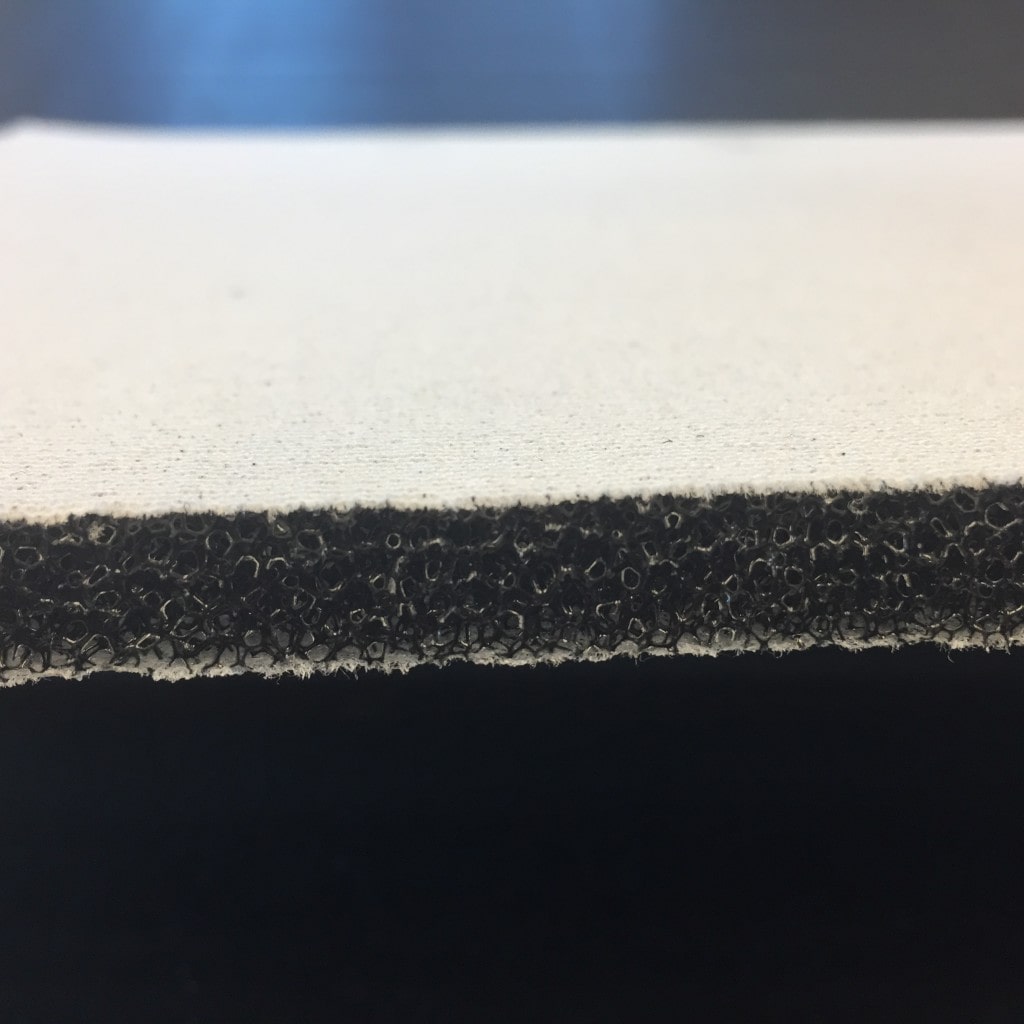

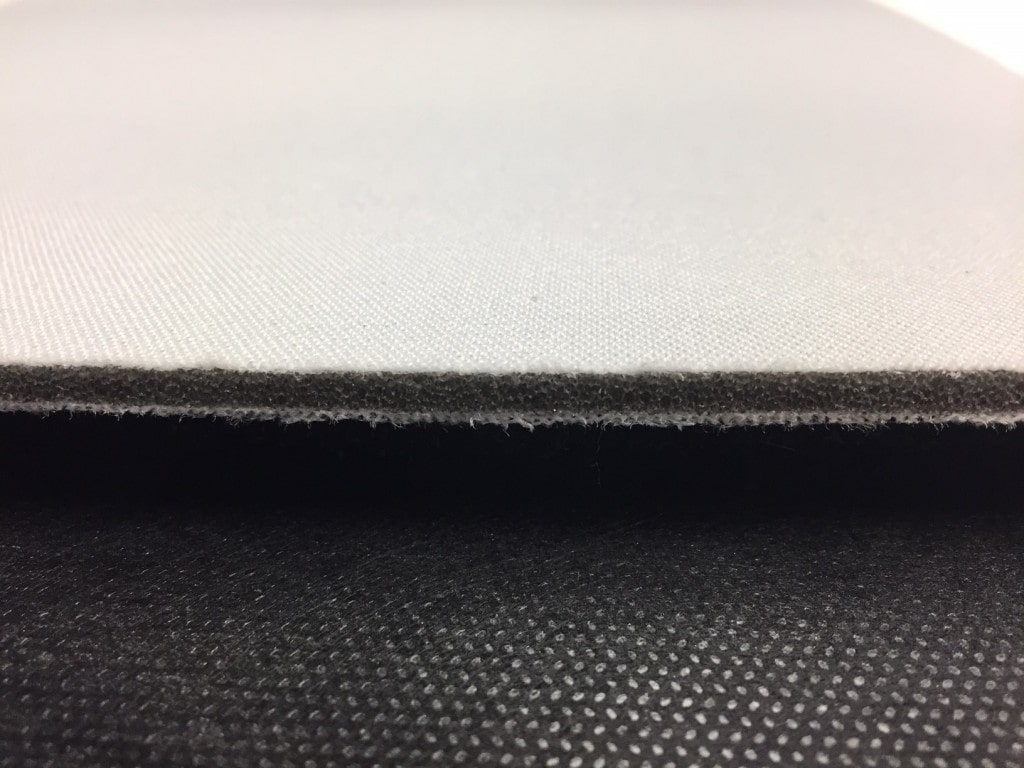

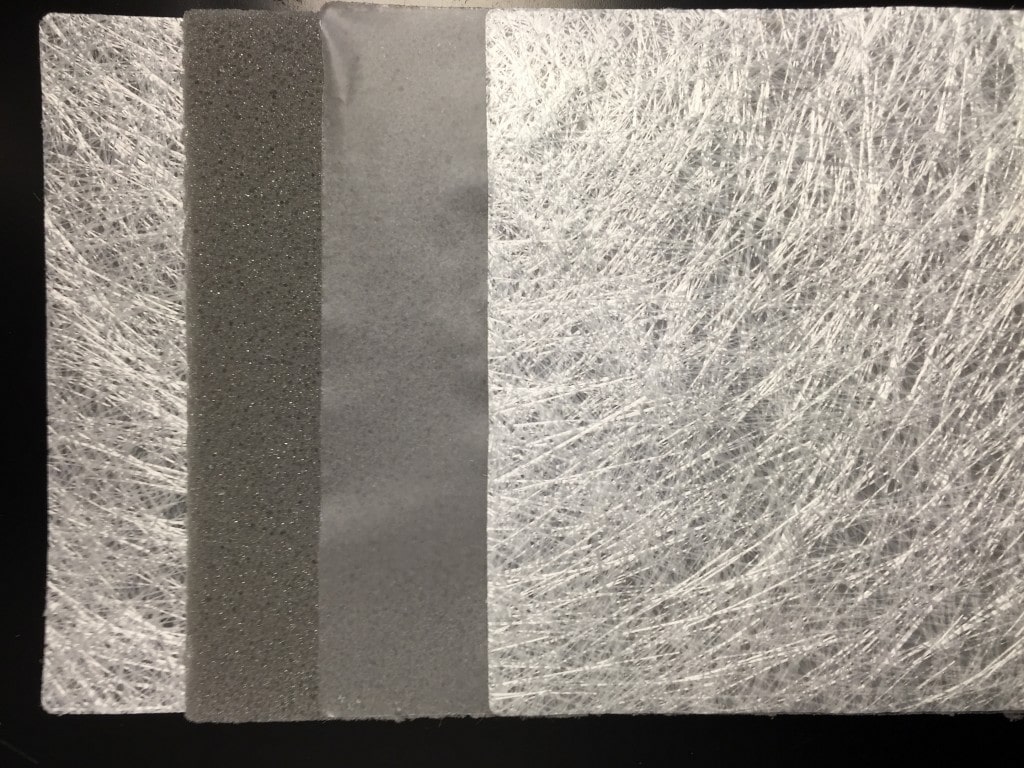

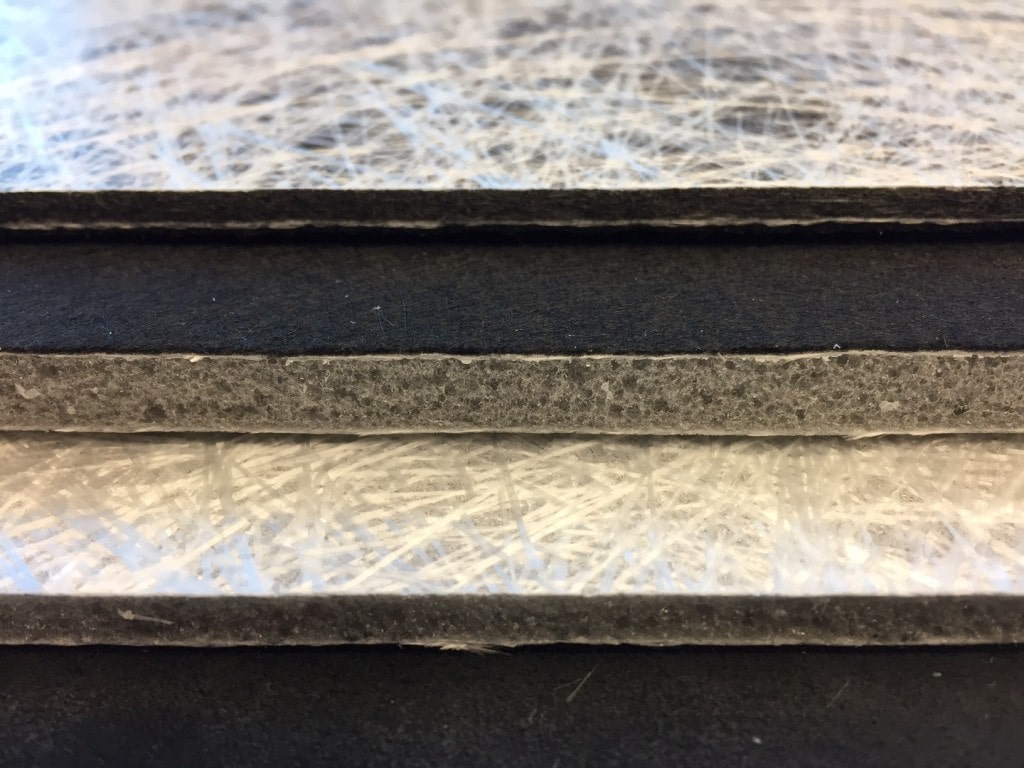

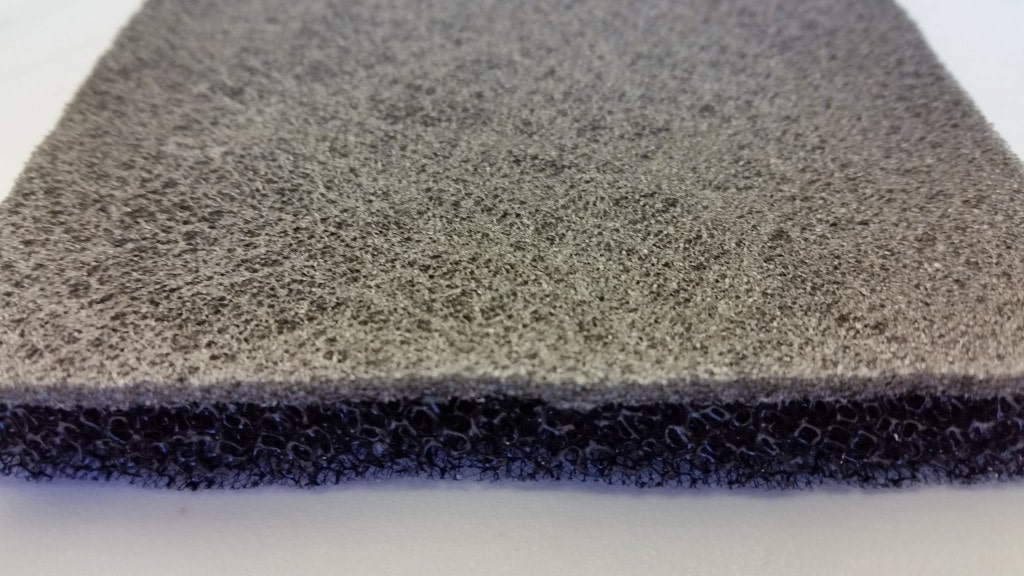

Multilayer composite lamination involves the bonding of multiple layers of different materials to create a strong and integrated composite structure. This technique utilizes adhesive layers and specialized bonding processes to achieve a seamless and durable bond between materials, ensuring optimal performance and longevity. -

Applications in the Automotive Industry:

2.1 Climate Control Seats:

Multilayer composite lamination is widely used in the manufacturing of climate control seats, ensuring the efficient bonding of different materials like fabric, foam, and heating elements. This process enables the creation of comfortable and temperature-regulated seating systems, enhancing the driving experience for vehicle occupants.2.2 Door Bolsters Trim:

In automotive interiors, door bolsters trim requires robust bonding to maintain its shape and withstand daily wear and tear. Multilayer composite lamination provides a reliable and aesthetically pleasing bond, ensuring the longevity and structural integrity of door bolsters trim components.2.3 Instrument Panel Trim:

Instrument panel trim requires precise and durable bonding to maintain its form and finish. Multilayer composite lamination enables efficient bonding of materials such as plastics, vinyl, and decorative elements, ensuring a high-quality and visually appealing instrument panel for automotive interiors.2.4 Center Console Trim:

Center consoles play a crucial role in automotive interiors, providing storage and control interfaces. Multilayer composite lamination allows for efficient bonding of various materials, including plastics, leather, and decorative accents, resulting in durable and visually appealing center console trim components.2.5 Headliners:

Headliners require efficient bonding to maintain their shape, acoustic properties, and overall aesthetics. Multilayer composite lamination ensures a strong bond between materials like fabrics, foams, and backing substrates, providing reliable and visually pleasing headliners for automotive interiors.2.6 Rigid Urethane Load Floors:

Rigid urethane load floors in automotive applications require robust bonding to withstand heavy loads and provide structural support. Multilayer composite lamination allows for efficient bonding of urethane materials, ensuring load floors that are strong, durable, and capable of withstanding demanding conditions. - Advantages of Multilayer Composite Lamination:

•Enhanced bond strength:

Multilayer composite lamination creates strong and durable bonds between materials, providing structural integrity and reliability.•Aesthetically pleasing finishes:

This lamination technique ensures seamless and visually appealing bonds, enhancing the overall appearance of automotive and industrial components.•Efficient manufacturing process:

Multilayer composite lamination allows for streamlined production, reducing assembly time and costs while maintaining high-quality standards.•Versatile bonding capabilities:

This technique enables the bonding of various materials, including fabrics, foams, plastics, and decorative elements, offering versatility in design and application.•Improved product performance:

Multilayer composite lamination enhances the overall performance of automotive and industrial components, ensuring durability, resistance to environmental factors, and optimized functionality.

Available Products:

Custom weights, widths, and constructions are available

Typical Markets & Applications:

Automotive:

• Climate control seats

• Door bolsters trim

• Instrument panel trim

• Center console trim

• Headliners

• Rigid urethane load floors

Multilayer composite lamination is a key enabler in the automotive and industrial sectors, providing efficient bonding for a wide range of materials. With its application in climate control seats, door bolsters trim, instrument panel trim, center console trim, headliners, and rigid urethane load floors, this advanced lamination technique ensures the durability, aesthetics, and functionality of critical components. Embracing multilayer composite lamination enables automotive and industrial manufacturers to deliver high-quality products that meet the demanding requirements of their respective industries.