Absorbers & Damping Products

HR Technologies specializes in multilayer custom engineered acoustical composites for automotive, marine, commercial trucks, military, and industrial applications. Our experienced team can help you find the best solution for your next noise, vibration, or harshness concern. Do you have your own idea, but need proof of concept? HR Technologies can support your needs from development to mass production.

In various industries, the need for effective noise and vibration control has never been more crucial. Our extensive range of absorbers and damping products, including textile composites, fabric composites, foil composites, melamine foam composites, polyurethane foam composites, polyether & polyester, and thermoformable semi-rigid polyurethane foam, are designed to address these challenges and optimize performance in your applications.

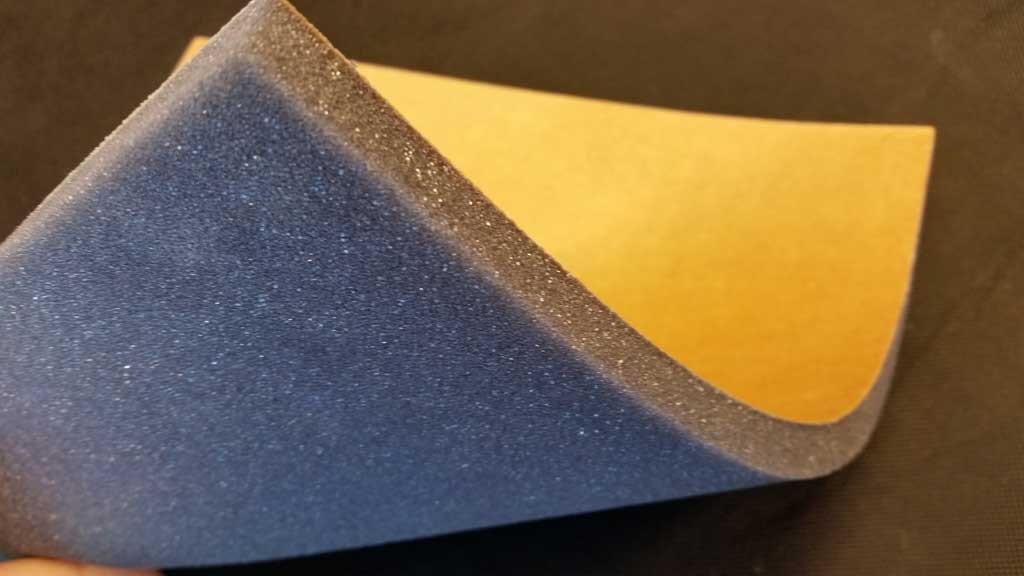

Textile Composites:

Textile composites combine the flexibility and strength of textiles with the added benefits of sound absorption and vibration damping. These versatile materials are used in automotive interiors, building acoustics, industrial machinery, and more. Their excellent noise reduction properties make them ideal for creating quieter and more comfortable environments.Fabric Composites:

Fabric composites offer exceptional soundproofing and damping capabilities while providing an aesthetically pleasing finish. They find applications in architectural acoustics, interior design, and automotive industries. Fabric composites effectively reduce noise transmission and vibrations, enhancing the overall acoustic experience.Foil Composites:

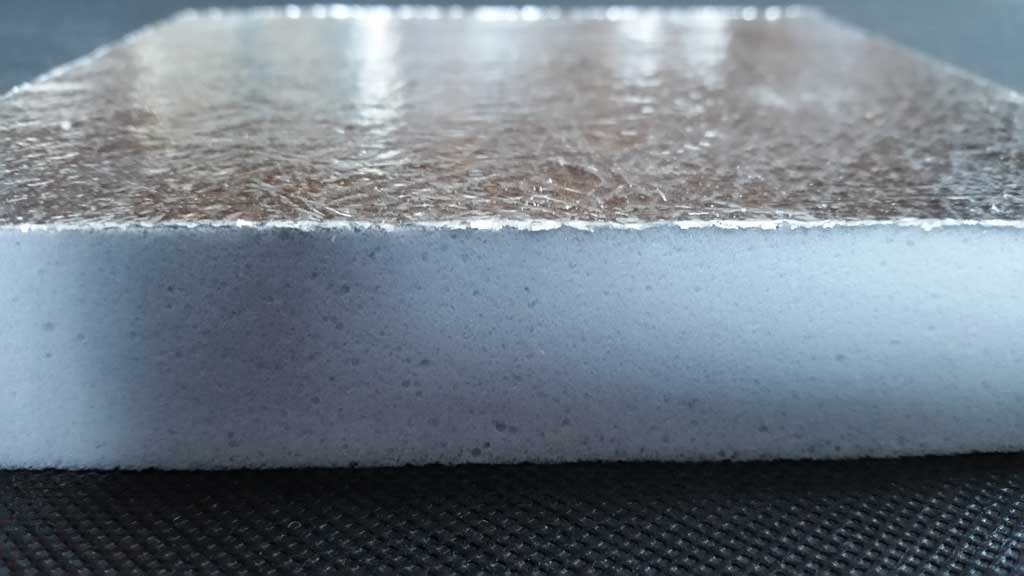

Foil composites are composed of a metallic foil layer combined with damping materials, providing excellent noise control and heat insulation properties. These composites are commonly used in HVAC systems, automotive components, and aerospace applications, where both sound reduction and thermal management are essential.Melamine Foam Composites:

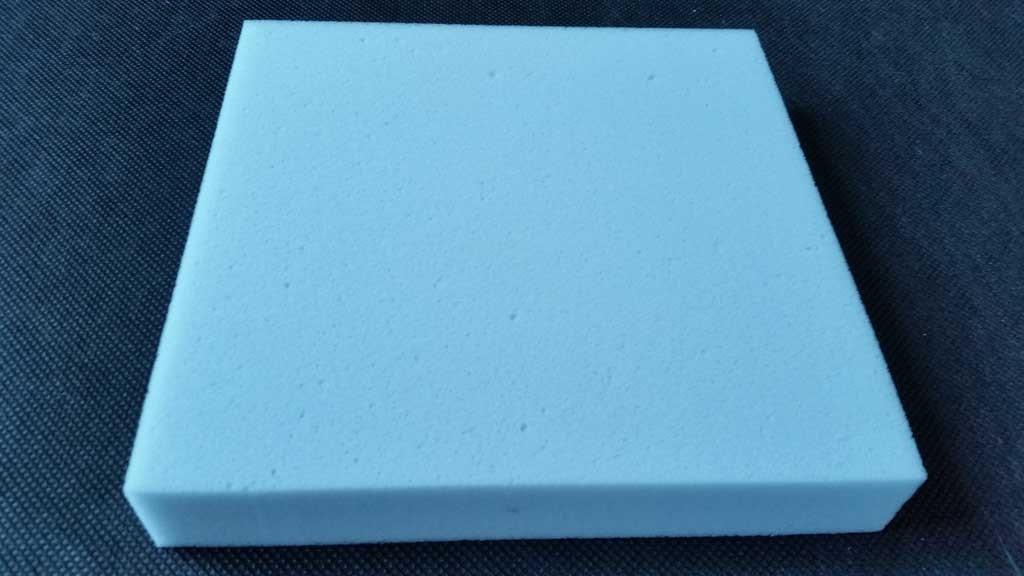

Melamine foam composites exhibit exceptional sound absorption characteristics. They are lightweight, fire-resistant, and widely used in construction, transportation, and industrial sectors. By absorbing sound energy across a broad frequency range, melamine foam composites effectively reduce noise levels and improve acoustic comfort.Polyurethane Foam Composites:

Polyurethane foam composites are renowned for their superior sound absorption and vibration damping capabilities. They are commonly employed in automotive interiors, machinery enclosures, and architectural applications. Polyurethane foam composites not only reduce noise but also enhance product performance and durability.Polyether & Polyester:

Polyether and polyester-based absorbers and damping products offer a versatile solution for various industries. These materials excel in sound absorption, vibration control, and impact resistance. They find applications in automotive, electronics, and consumer goods, providing improved product performance and enhanced user experience.Thermoformable Semi-Rigid Polyurethane Foam:

Thermoformable semi-rigid polyurethane foam combines flexibility and structural stability. It can be molded into different shapes, making it ideal for complex applications that require customized solutions. This foam material offers excellent vibration damping properties, ensuring optimal performance and durability.

When it comes to noise and vibration control, absorbers and damping products play a vital role in improving performance and efficiency across numerous industries. Our diverse range of textile composites, fabric composites, foil composites, melamine foam composites, polyurethane foam composites, polyether & polyester, and thermoformable semi-rigid polyurethane foam provides tailored solutions to meet your specific requirements. Experience the benefits of enhanced acoustics, reduced vibrations, and improved product quality with our high-quality absorbers and damping products.

Available Products:

- Textile composites

- Fabric composites

- PVC & PUR vinyl composites

(perforated and non-perforated)

- Foil composites

- Film composites

- PE, EVA, PP, TPU, CoPA, CoPES, and PES films

- Melamine foam composites

- Density: .5 pcf

- Polyurethane foam composites

- Polyether & Polyester

- Typical Density: 1.5pcf – 6.0pcf

- Typical IFD: 10-250

- Flammability: FMVSS302 & UL94 VO

- Convolute Cut

- Thermoformable Semi-Rigid Polyurethane Foam

These cutting-edge techniques are revolutionizing the precision control of materials, allowing for remarkable versatility and enhanced quality. Whether you’re working with PP & Glass Needled fiber, Fiberglass Textiles, PET Shoddy / Felt, Polyurethane foam, or any other thermally set material, the process of flatbed consolidation and heat setting opens up a world of possibilities. In this article, we will delve into the benefits, applications, and advantages of this innovative approach, while shedding light on how it can significantly boost the performance of various materials.