Flatbed Lamination

Flatbed Lamination

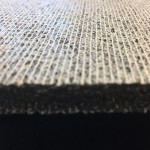

HR Technologies has 26+ years of thermoplastic belt lamination experience. All of our flatbed machines are double belt laminators with both heating and cooling zones for precision lamination and excellent bonds. Our equipment has been modified to handle even the toughest multilayer lamination requests in rolls, sheets, or pieces. Our technical experts are up for any technical composite challenge you can dream up!

Our equipment is very versatile. It’s not only for creating unique multilayer composites, but it can also be used to thermoset materials to customer specific thickness requirements. HR Technologies has the capability to lock in material thicknesses by using our flatbed belt press process. If thickness control and tight tolerances are important we just might be your solution!

Process parameters:

- Temperature

- Speed

- Pressure

- Gap

- Height

Typical Process Inputs

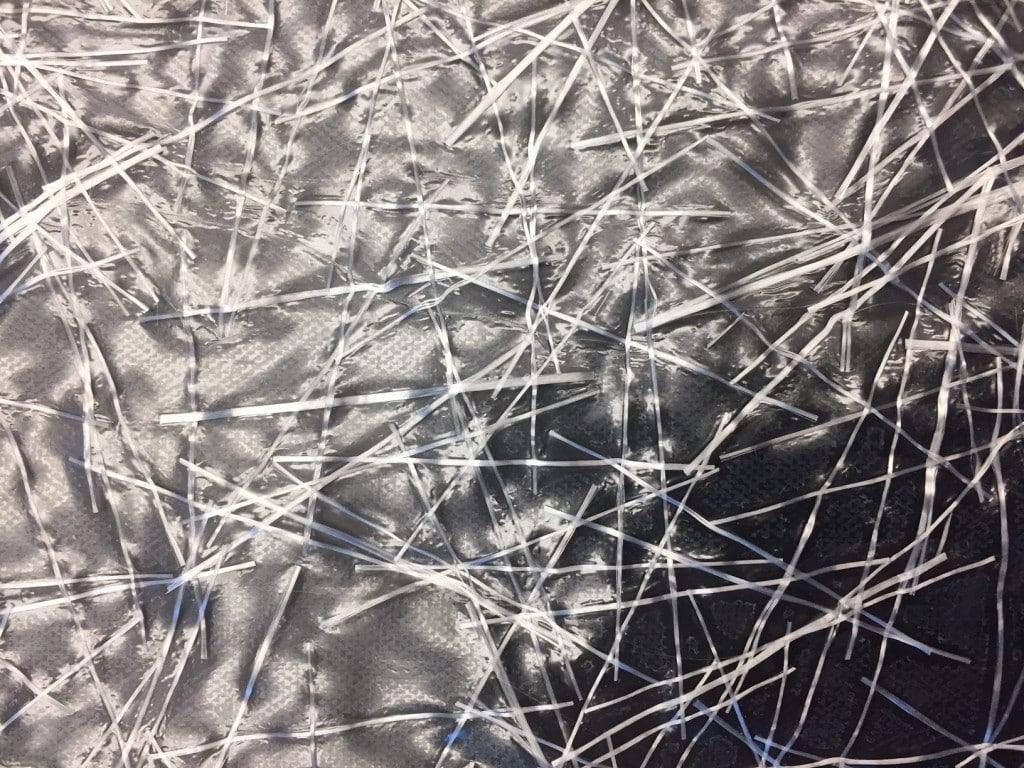

- E glass roving’s

- Thermoplastic adhesives

– Scatter powder adhesives

– Adhesive & barrier films

– Web adhesives - Carrier substrate

– Textiles

–Open cell foams

–Closed cell foams

–Reticulated foams

–PET fiber

–PET Pointbond/spunbond

–Foils

–others - PSA (Pressure sensitive adhesive)

–Rubber and Acrylic - Multiple inputs

–Capable of up to 6 inputs in one process pass!

Typical Products:

Custom weights, widths, and constructions are available