Polyurethane Foam Pouring & Processing

Polyurethane Foam Pouring

When it comes to construction and insulation projects, polyurethane foam pouring has become increasingly popular due to its exceptional versatility and superior performance. If you’re searching for reliable polyurethane foam pouring services, you’ve come to the right place. Our company is dedicated to delivering top-notch solutions that cater to your unique requirements, ensuring enhanced durability, energy efficiency, and overall project success. Read on to explore the advantages and various applications of polyurethane foam pouring and discover why we are the preferred choice in the industry.

Benefits of Polyurethane Foam Pouring:

Exceptional Insulation Properties: Polyurethane foam offers outstanding thermal insulation capabilities, making it an ideal choice for projects that require energy efficiency and reduced heat transfer. It forms a seamless and airtight barrier that minimizes air leakage, preventing heat loss and improving indoor comfort.

Structural Support and Stability: Polyurethane foam pouring provides excellent structural support and stability to various applications. It can be used for filling voids, cavities, and gaps, ensuring enhanced load-bearing capacity and reducing the risk of structural damage.

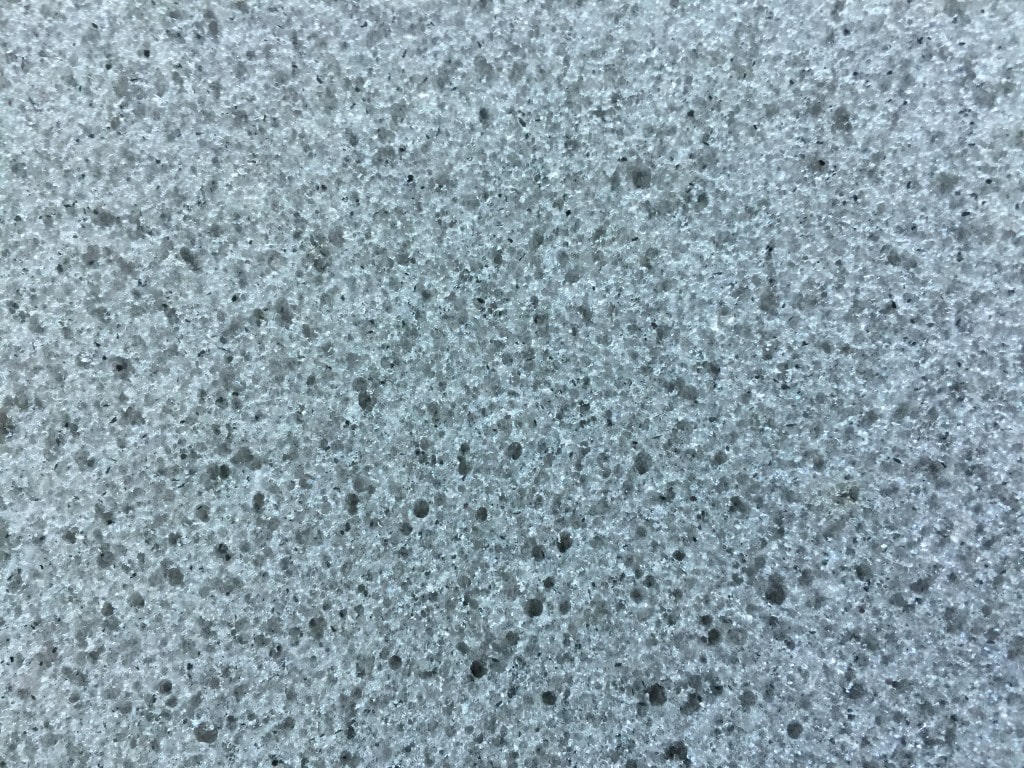

Moisture and Vapor Barrier: The closed-cell structure of polyurethane foam makes it impermeable to moisture and acts as an effective vapor barrier. This feature is particularly valuable in applications such as roofing, foundations, and crawl spaces, where protection against water intrusion is crucial.

Noise Reduction: Polyurethane foam has excellent sound-absorbing properties, reducing the transmission of airborne and impact noise. This makes it an excellent choice for soundproofing walls, floors, and ceilings, creating a quieter and more comfortable environment.

Versatility: Polyurethane foam pouring can be applied to various surfaces and substrates, including concrete, wood, metal, and more. Its ability to conform to irregular shapes and surfaces ensures a seamless and efficient installation process.

Applications of Polyurethane Foam Pouring:

Building Insulation: Polyurethane foam pouring is extensively used in residential, commercial, and industrial buildings for insulation purposes. It helps maintain consistent indoor temperatures, lowers energy consumption, and reduces HVAC system workload.

Roofing Systems: Polyurethane foam acts as a seamless protective layer on roofs, offering excellent insulation, waterproofing, and resistance to weathering. It eliminates the need for traditional roofing materials, reducing overall costs and improving longevity.

Concrete Lifting and Leveling: Polyurethane foam can be injected beneath settled concrete slabs, sidewalks, and driveways to lift and level them. This technique provides a cost-effective solution to repair sunken or uneven surfaces without the need for extensive excavation.

Marine and Automotive Industries: Polyurethane foam is widely used in marine and automotive applications for buoyancy, flotation, insulation, and soundproofing. It ensures structural integrity, improves fuel efficiency, and enhances passenger comfort.

Why Choose Our Polyurethane Foam Pouring Services:

Expertise and Experience: Our team consists of highly skilled professionals with extensive experience in polyurethane foam pouring. We understand the unique requirements of each project and provide tailored solutions for optimal results.

Quality Assurance: We are committed to delivering the highest quality standards in every aspect of our service. From the materials we use to our application techniques, we prioritize excellence to ensure customer satisfaction and project success.

Timely and Efficient Execution: We understand the importance of meeting project deadlines. Our team works diligently to complete each job within the specified timeframe while maintaining exceptional workmanship and attention to detail.

Competitive Pricing: We offer competitive pricing without compromising on the quality of our services. Our transparent pricing structure ensures affordability and value for your investment.

Customer Satisfaction: Our priority is your satisfaction. We strive to exceed your expectations by providing exceptional customer service, clear communication, and ongoing support throughout the project.

Polyurethane foam pouring is a versatile and effective solution for a wide range of construction and insulation needs. With our professional polyurethane foam pouring services, you can enhance the performance and durability of your projects while enjoying benefits such as excellent insulation, structural support, moisture resistance, noise reduction, and more. Trust our experienced team to deliver top-quality results, ensuring your satisfaction and project success. Contact us today to discuss your requirements and discover how we can transform your project with polyurethane foam pouring.

Semi-Rigid Polyurethane Foam Processing

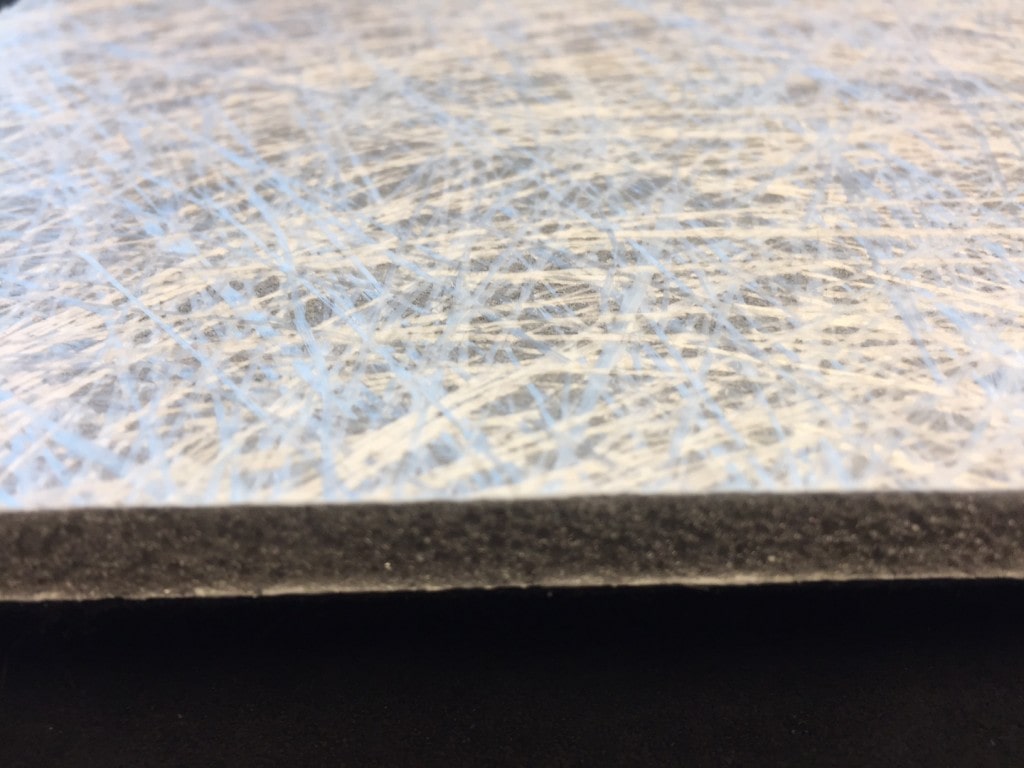

HR Technologies specializes in semi-rigid polyurethane foam blocks specifically designed for the lightweight core layer used in the headliner, sunshade, and under hood applications.

HR Technologies can supply slit to size foam sheets, or Thermoformable TRU composite boards. Our slitting and lamination equipment is capable of holding the extremely tight tolerances needed by our customers hot and cold mold forming processes.

Foam Slitting Process:

PU Foam Blocks

Prep

Cut

Sheet Inspection & Packing

Typical Products:

• Headliners

• Sunshades / Moon Roofs

• Hoodliners

• Under hood absorbers