Adhesives Coatings, Films, Webs & PSA’s

HR Technologies specializes in finding the most cost effective thermoplastic adhesive options for your project. Thermoplastic adhesives have revolutionized the adhesive industry, offering superior bonding capabilities in various forms such as coatings, films, webs, and pressure-sensitive adhesives (PSA’s).

We work with the industry leading adhesive manufacturers to bring our customers a diverse portfolio of adhesive lamination and back coating options. HR Tech will create customized solutions using webs, films, powders, or hot melts to meet your specific processing needs.

Understanding Thermoplastic Adhesives:

Thermoplastic adhesives are a class of adhesives that become soft and pliable when heated and solidify upon cooling. They provide excellent adhesion to various substrates, offering high bond strength and flexibility. The unique properties of thermoplastic adhesives make them suitable for a wide range of applications.

Applications of Thermoplastic Adhesives:

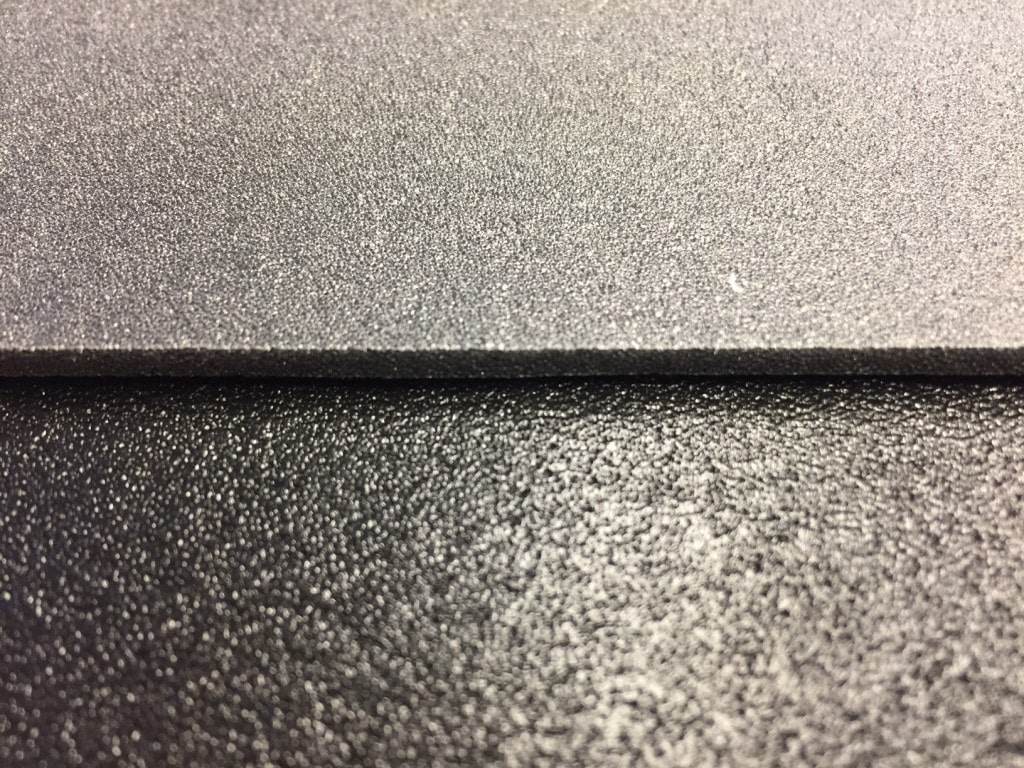

2.1 Coatings:

Thermoplastic adhesive coatings provide a protective and adhesive layer to surfaces, enhancing their performance and durability. These coatings are used in industries such as automotive, aerospace, electronics, and packaging, where they provide corrosion resistance, insulation, and adhesion to substrates

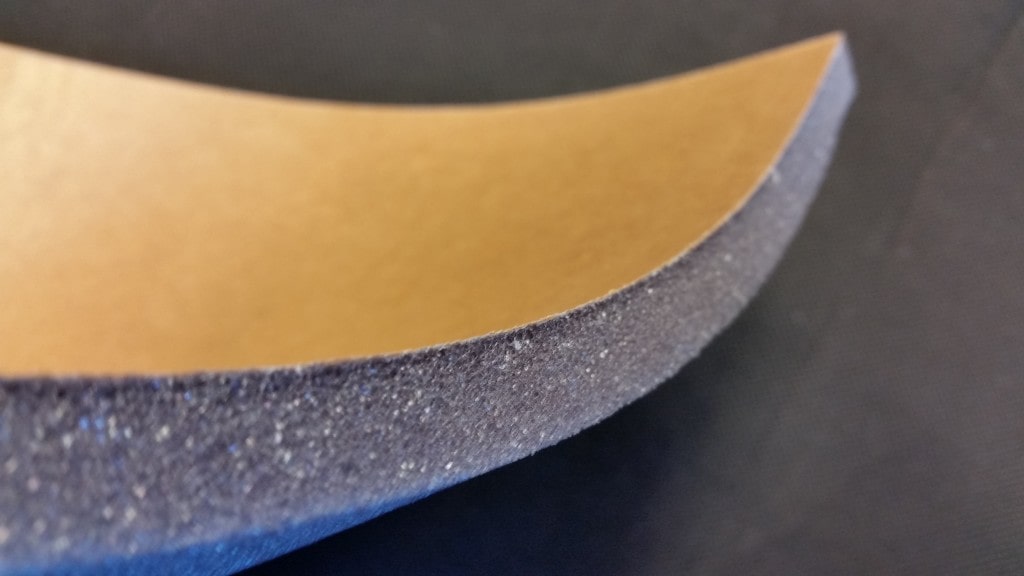

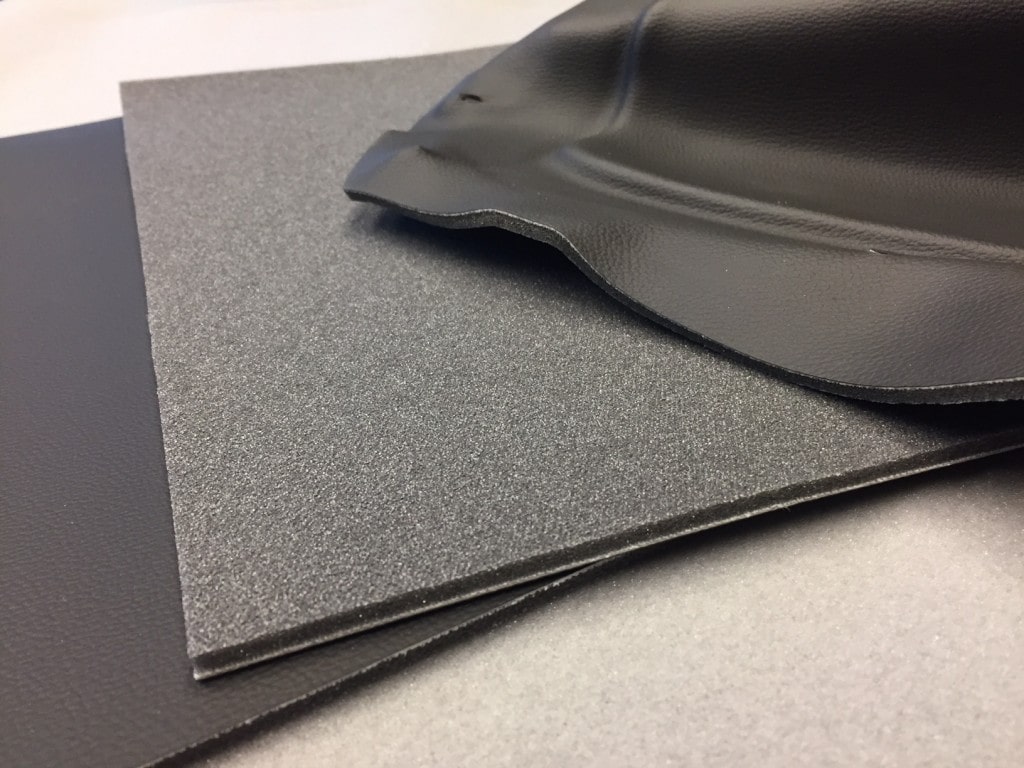

2.2 Films:

Thermoplastic adhesive films offer a convenient and versatile solution for bonding applications. These films can be easily applied to surfaces using heat and pressure, creating strong bonds. They are commonly used in industries such as automotive, construction, medical, and electronics, providing adhesion, sealing, and protection

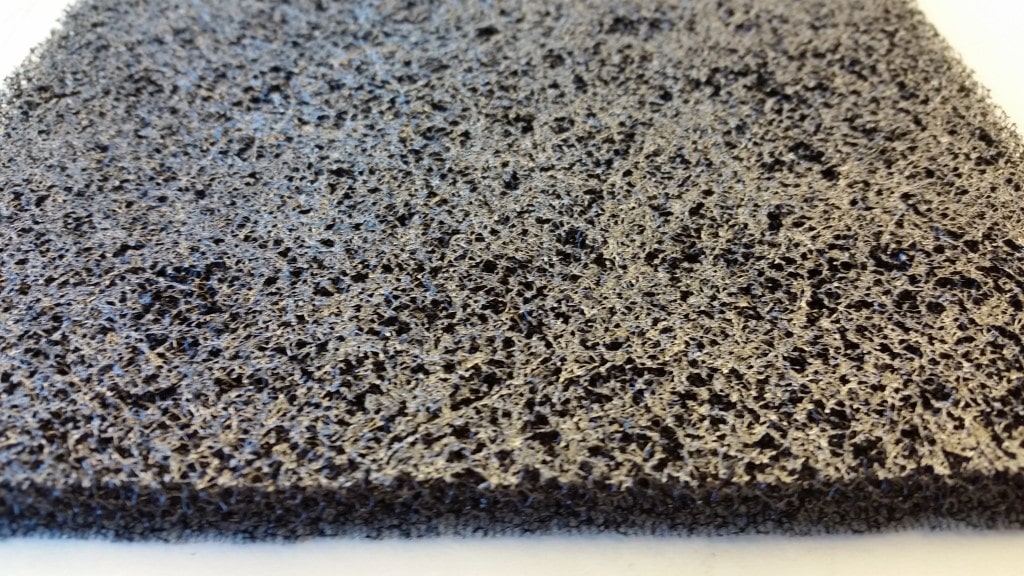

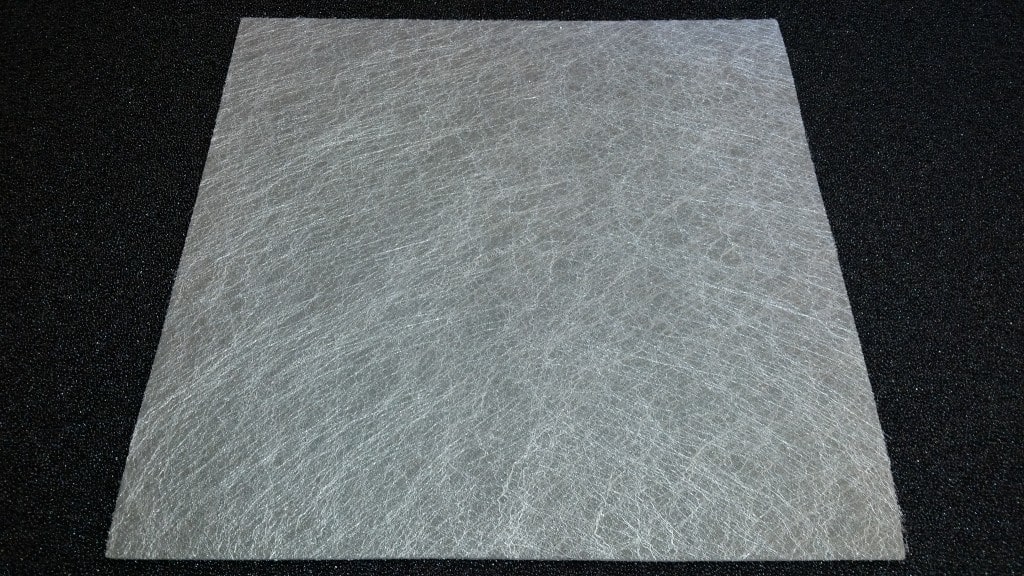

2.3 Webs:

Thermoplastic adhesive webs consist of a nonwoven or woven material coated with a layer of adhesive. These webs are used in industries like textiles, automotive, and filtration, where they provide bonding, lamination, and filtration capabilities. They are often utilized for joining different fabrics, creating composite structures, and enhancing product performance.

2.4 Pressure-Sensitive Adhesives (PSA’s):

Thermoplastic pressure-sensitive adhesives (PSA’s) offer an excellent balance between tackiness, adhesion, and removability. They are commonly used in industries such as packaging, labels, tapes, and medical devices. These adhesives form an instant bond upon contact and can be easily removed without leaving residue or damaging surfaces.

- Benefits of Thermoplastic Adhesives:

• Strong adhesion:

Thermoplastic adhesives provide excellent bond strength to a wide range of substrates, ensuring reliable and durable adhesion.

• Flexibility and versatility:

These adhesives offer flexibility in application and can be customized to meet specific requirements. They can be applied as coatings, films, webs, or PSA’s, catering to diverse industry needs.

• Easy processing:

Thermoplastic adhesives can be easily processed using heat and pressure, making them suitable for various manufacturing techniques, including hot-melt and heat-activated applications.

• Quick bonding:

Thermoplastic adhesives provide fast bonding times, allowing for increased production efficiency and reduced assembly time.

• Temperature resistance:

These adhesives exhibit excellent temperature resistance, maintaining their adhesive properties under challenging environmental conditions.

Available Products:

Adhesive & barrier films:

• PE

• EVA

• PP

• TPU

• CoPA

• CoPES

• PES films

Web adhesives:

• CoPA

• CoPES

• Polyolefin

• PP

• PU

Back Coating:

• Hot melt

• Polyurethane reactive adhesives (PUR),

• Ethylene-vinyl acetate adhesives (EVA)

Scatter powder adhesives:

Thermoplastic powders

Pressure sensitive adhesives (PSA)